Temperature control is a fundamental aspect of food storage, ensuring the safety and quality of perishable goods. Maintaining the right temperature helps slow the growth of harmful bacteria and pathogens, which can cause foodborne illnesses. For instance, meat, dairy, and fresh produce need to be stored at specific temperatures to prevent spoilage and ensure they remain safe for consumption.

Humidity plays a crucial role in food storage, directly influencing various food items’ shelf life, quality, and safety. High humidity levels can accumulate moisture, creating an ideal environment for mold, bacteria, and other microorganisms to thrive, especially on perishable goods like fruits, vegetables, and bread. Conversely, low humidity can cause foods like fresh produce to dehydrate, leading to wilting, shriveling, and loss of nutritional value. The storage of dry goods such as grains and spices depends heavily on humidity control, as excessive moisture can lead to clumping, spoilage, and pest infestations. Proper humidity regulation is essential in both commercial and domestic storage settings, achieved through technologies like dehumidifiers, moisture-resistant packaging, and controlled environments such as refrigerators and climate-controlled storage units. By maintaining optimal humidity levels, food can be preserved for longer periods, reducing waste and ensuring that it remains safe and palatable for consumption.

The Critical Role of Temperature and Humidity in Food Storage with Data Loggers: Ensuring Safety and Efficiency

Have you ever wondered how companies keep track of temperature, humidity, or other critical variables in real time? In today’s data-driven world, the answer often lies in a powerful tool known as a data logger. But with so many options and features available, how do you know which one is right for your needs?

Data loggers have become indispensable across various industries, from food safety to environmental monitoring. These small, portable devices are designed to collect and store data over time, allowing businesses to make informed decisions and maintain standards. However, with the rapid advancement of technology and the plethora of choices available, navigating the data logger landscape can be overwhelming.

Whether you’re a researcher, a quality control manager, or just someone keen on tracking specific environmental conditions, understanding the ins and outs of data loggers is crucial. Choosing the right data logger can mean the difference between simplified data collection and a frustrating experience.

In this blog, we’ll explore everything you need to know about data loggers, their applications, and how to select the perfect model to meet your unique requirements.

Industrial Necessity: Why Temperature Control Matters

In industrial settings, temperature control is crucial for various processes and products. Many industrial applications, such as chemical manufacturing, pharmaceuticals, and electronics, require precise temperature regulation to ensure product quality and safety. For example, in pharmaceutical production, maintaining the correct temperature is essential for preserving the efficacy of drugs and vaccines.

Moreover, temperature control helps in optimizing energy consumption and operational efficiency. By closely monitoring and regulating temperature, industries can reduce energy waste, lower operational costs, and minimize the risk of equipment failure. This not only ensures the smooth functioning of industrial processes but also contributes to sustainability goals by reducing the carbon footprint.

Consequences of Neglecting Temperature Monitoring

Neglecting temperature monitoring can lead to several adverse consequences, both in food storage and industrial settings. In the food industry, failing to monitor and control temperature can result in spoilage, foodborne illnesses, and significant financial losses. Spoiled food products not only pose health risks to consumers but also damage the reputation of food producers and retailers.

In industrial environments, inadequate temperature monitoring can cause equipment malfunction, production downtime, and compromised product quality. For instance, in the chemical industry, temperature fluctuations can lead to unsafe chemical reactions, posing significant safety hazards. Overall, the lack of proper temperature monitoring can have severe implications for product integrity, safety, and operational efficiency.

Case Study: The Impact of Temperature Fluctuations in Cold Storage

Consider a cold storage facility used for storing perishable food items such as fruits, vegetables, and dairy products. If the temperature fluctuates beyond the recommended range, even for a short period, it can lead to spoilage and significant financial losses. For example, if the temperature rises too high, it can accelerate the ripening process of fruits, leading to premature spoilage. Similarly, dairy products can become unsafe for consumption if stored at incorrect temperatures.

A specific instance involved a cold storage facility that experienced a malfunction in its refrigeration system, causing temperatures to rise unexpectedly. As a result, several tons of stored produce were spoiled, leading to substantial financial losses and supply chain disruptions. This case underscores the importance of continuous temperature monitoring and the need for reliable systems to detect and alert any deviations promptly.

Understanding Data Loggers: What They Are and Why They’re Essential

Data loggers are electronic devices used to record and monitor environmental parameters over time, such as temperature, humidity, and pressure. They are equipped with sensors that capture data at regular intervals, which are then stored for analysis.

The primary advantage of using data loggers is their ability to provide continuous and accurate data collection, enabling proactive measures to maintain optimal conditions. They help in identifying trends, detecting deviations, and ensuring compliance with regulatory standards. Additionally, data loggers can be integrated with alarm systems to provide real-time alerts, allowing for immediate corrective actions. Overall, data loggers are indispensable for maintaining safety, quality, and efficiency in temperature-sensitive applications.

In today’s fast-paced and precision-driven industries, maintaining optimal temperature conditions is essential for ensuring both safety and efficiency. From food storage to pharmaceuticals, a cold storage understanding of the pivotal role of temperature monitoring can make all the difference.

Overview of Data Loggers: Types and Functions

Primarily, data loggers can be categorized into single-use and multi-use devices. Additionally, data loggers with external sensors offer enhanced accuracy for specialized applications. Each type has its unique advantages, making them indispensable tools in ensuring optimal conditions are maintained.

Single-Use Data Loggers: Cost-Effective and Efficient Solutions

Single-use data loggers are designed for one-time use, making them a cost-effective solution for short-term monitoring needs. These devices are typically used during the transportation of sensitive goods where data needs to be recorded and reviewed upon arrival.

Their low cost and ease of use make them ideal for industries that require reliable yet economical monitoring solutions. Once the data is retrieved, the devices are disposed.

Multi-Use Data Loggers: Versatility and Long-Term Multi-use data loggers are designed for repeated use over an extended period, offering long-term monitoring solutions. These devices can be recalibrated and reused, making them a versatile and cost-effective option for ongoing temperature monitoring needs.

Their durability and ability to store large amounts of data make them suitable for industries that require continuous monitoring, such as manufacturing and pharmaceuticals. Over time, the investment in multi-use data loggers can result in significant cost savings and enhanced operational efficiency.

Data Loggers with External Sensors: Enhanced Accuracy and Applications

Data loggers equipped with external sensors offer enhanced accuracy and are suitable for specialized applications where precise measurements are critical. These sensors can be placed directly in the environment being monitored, providing real-time data with high accuracy.

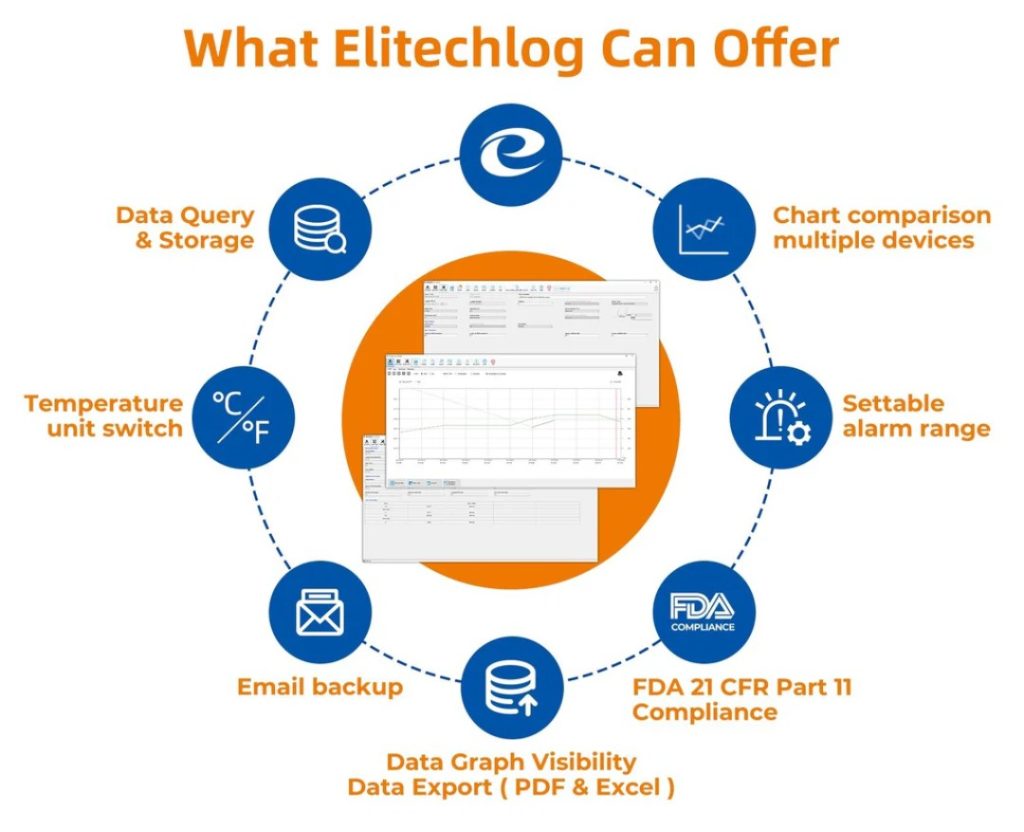

Instrukart, an authorized distributor for Elitech data loggers, offers a wide range of high-quality, user-friendly logging devices that cater to diverse applications. With Elitech’s innovative solutions, businesses can efficiently track their environmental conditions in real time, ensuring product safety and integrity. By leveraging the latest technology, Instrukart ensures that customers receive not only top-tier data loggers but also the support necessary for their effective utilization, making it easier to maintain optimal operational standards.